English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

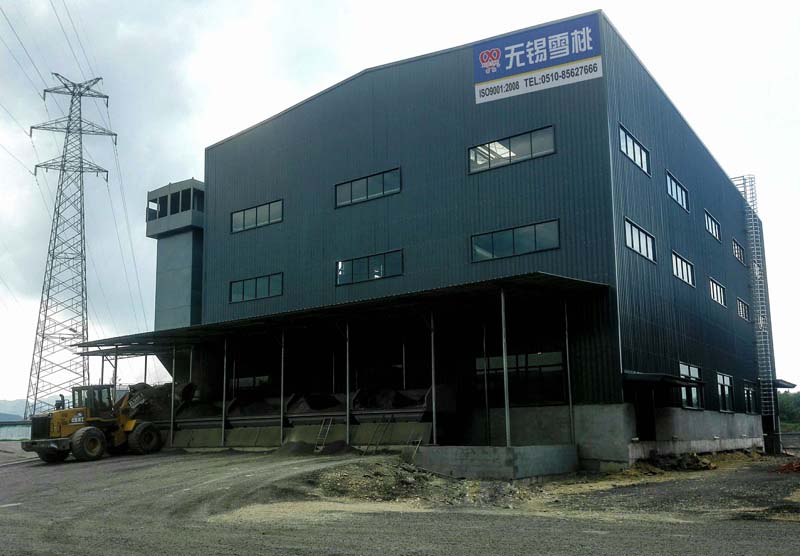

In-House Environmental 240TPH Asphalt Mixing Plant

CXTCM In-House Environmental 240TPH Asphalt Mixing Plant adapted to the requirements of urban environment. It can not only meet the requirements of government departments for environmental protection, but also meet the construction needs of asphalt mixture. It is Modular flow design, The highest point of asphalt plant is no more than 18.5 meters, full computer automatic control. Equipped with necessary Environmental protection device for some parts where will have smell, dust and noise.

Send Inquiry

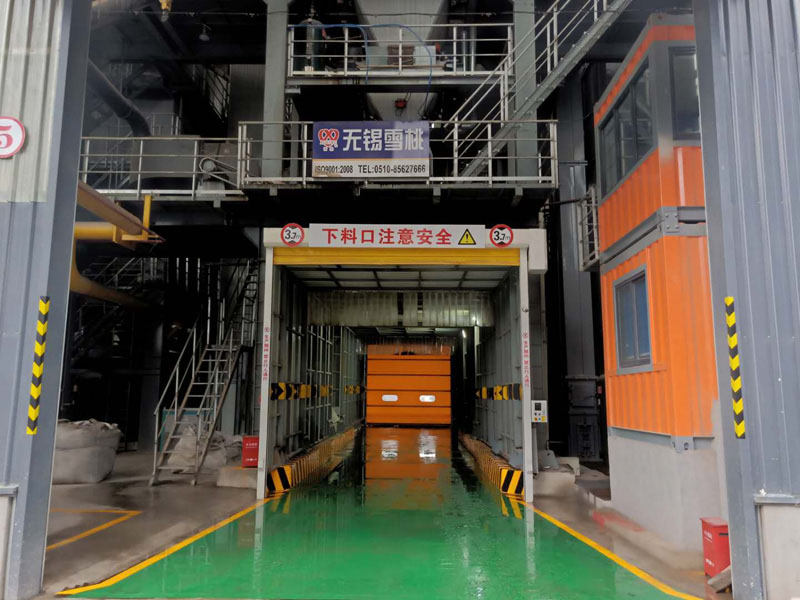

240TPH In-House Environmental Asphalt Mixing Plant is CXTCM designed for meeting the requirements of urban environment. The model is IH·AMP240. It can not only satisfied the requirements of government departments for environmental protection, but also meet the construction needs of asphalt mixture. Modular flow design makes sure the highest point of asphalt plant is not more than 18.5 meters. It can be built in the house which height won’t be higher than 22m. It looks like a big factory from outside. Asphalt mixing plant can be perfectly matched to the surrounding environment. It equipped with necessary Environmental protection devices. It can effectively remove dust, asphalt smoke and noise in production, and is very friendly to the environment.

In-House Environmental 240TPH Asphalt Mixing Plant Parameter (Specification)

|

Model Specification |

IH·AMP240 |

|

Rated output (t/h) |

240 |

|

Mixer capacity (kg/batch) |

4000 |

|

Height of asphalt plant(m) |

18.5 |

|

Oil consumption (kg/t) |

≤6.5 |

|

Fuel |

Diesel oil, Heavy oil, Gas |

|

Product temperature(℃) |

130-240 |

|

Aggregate cumulative measurement accuracy (%) |

±0.33 |

|

Bitumen measurement accuracy (%) |

±0.18 |

|

Filler measurement accuracy (%) |

±0.22 |

|

Bitumen and aggregate ratio deviation (%) |

±0.3 |

|

Discharge temperature stability accuracy(℃) |

±5 |

|

Operating station noise [dB(A)] |

<70 |

|

Environmental noise plant boundary 7 meters [dB(A)] |

<85 |

|

Environmental noise plant boundary 30 meters [dB(A)] |

<70 |

|

Environmental noise plant boundary 50 meters [dB(A)] |

<68 |

|

Smoke blackness (Grade) |

≤1 |

|

Soot emission concentration (mg/Nm3) |

≤50 |

|

Drifting dust emission concentration (mg/Nm3) |

≤5.0 |

Reserve the right to change the parameters without prior notice.

In-House Environmental 240TPH Asphalt Mixing Plant Process Diagram

Comparison of Conventional and In-House Environmental Asphalt Mixing Plant

In-House Environmental Asphalt Mixing Plant is designed for the asphalt plant installed in the city.

Standard and conventional asphalt mixing plant’s disadvantages:

1. The height is about 25m.

2. Effect for the environment: Dust, noisy, smell.

2.1 Dust pollution cause:

● Loader, collecting conveyer loads and transports material cause the dust

● In production, negative pressure control is not good or broken connection somewhere cause the dust

● Cleaning mixer every day cause a lot of dust

● Open jobsite blowing dust

2.2 noisy pollution cause:

● Noisy from loader in working

● Noisy from the running dryer drum when aggregates friction inside

● Noisy from the hot elevator when it lifts the aggregates

● Noisy from the vibration screen deck in working

● Noisy from the mixer in working

● Noisy from blower fan in working(audio high, spread farther)

2.3 smell pollution cause

● Smell produced when unloading bitumen

● Smell produced when heating bitumen

● Smell produced when mixer discharge material and finished material discharge from storage silo

● Smell produced when burning the heavy oil

Comparison of Conventional and In-House Environmental Asphalt Mixing Plant’s advantages:

The Hangar “in-house” environmental protection asphalt plant achieve the environment requirements of city, consist with follow four system:

1.Lower elevation type asphalt plant, the top point is 15m.

2.fully enclosed workshop

3.ventilation and dust, smell remove system

3.1 ventilation circulation and dust collection device outside of the workshop (matched with workshop)

Although we have taken various environmental protection method on the asphalt plant, but there is always a very small amount of dust and smell remain internal, especially the taste will affect the work environment. It is necessary to make the air inside exchange with external constantly.

We equipped with air supply and exhaust system on the wall, so that indoor air can be circulated with new air outside. The air pumped to outside will be passed collecting and processing, thus ensure internal air environment while no polution for the external environmental pollution.

3.2 water automized spraying device(matched with workshop)

In general, there will be no dust generated in the plant, but there will be more dust when the accident occurs, it will affect the working environment inside. The problem can not be solved quickly by the conventional ventilation cycle, therefore, the device can be used as an emergency measure to quickly recover a good working environment.

At the top of the plant to install sprinkler system, the use of high pressure water pump to spray water, if the plant sudden dust increase, you can open the system, it can play the role of rapid dust removal

3.3 bitumen flue gas,dust collecting and disposal device(matched with asphalt plant)

Setting absorb flue gas and collecting dust system at the mixer discharge door;

Air-vent of bitumen tanks was connected by pipeline to burner;

Dust cover setting on the cold feed hoppers and conveyer;

3.4 Noisy remove device (matched with asphalt plant)

Hot elevator, vibration sieve, hot bin with external sound insulation and heat preservation device, can effectively reduce the friction sound of aggregate with steel.

3.5 Sulfur dioxide treatment device(matched with asphalt plant)

3.6 We put the air compressor, draught fan, filler silo and other parts that easily generated noisy and dust in a separate space inside, as far as possible to reduce the impact on the indoor environment.

4. other auxilary system

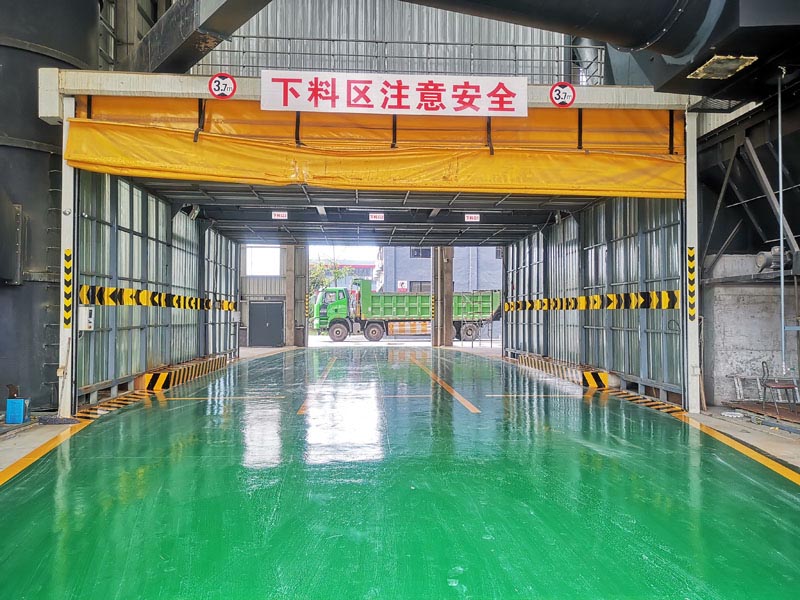

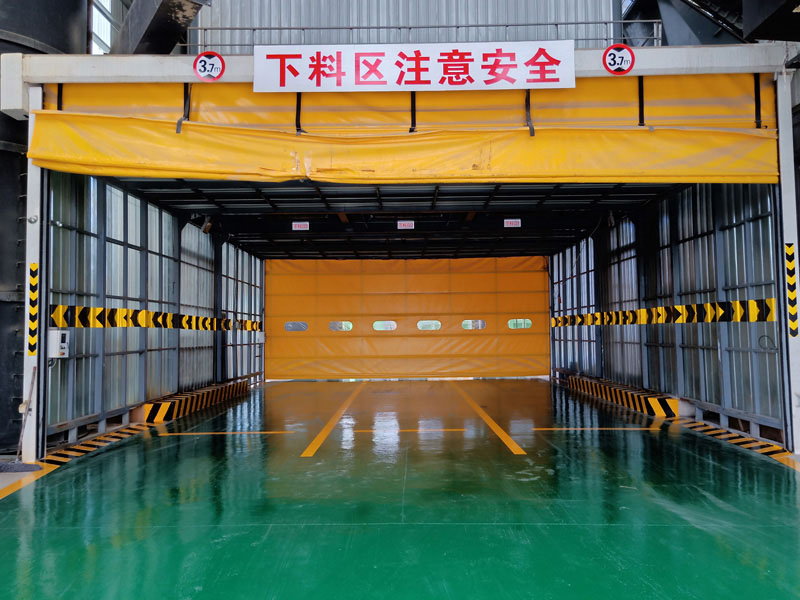

4.1 automatically loading material system

The workshop is divided into asphalt mixing plant installation area and raw material stacking area. The raw material stacking area uses an automatic feeding system, which can send the stone to the corresponding pile according to various specifications. The signal is transmitted to the computer through the material level device installed on the cold hopper during production, and the computer controls the grab bucket to send the material to the cold hopper where the stone needs to be added. Greatly reduced dust.

4.2 Track type mobile inspection trolley

Because In-House Environmental Asphalt Mixing Plant is installed indoors, there are more columns, and the crane is difficult to operate indoors, which brings great trouble to replace the parts.

According to the asphalt plant flow-type structure, centralized layout, low height characteristics, in the main equipment area design and installation of a set of track type mobile repair trolley, perfect solution to the equipment daily maintenance and repair. The device can lift all parts, no longer need crane, not only easy to use, but also save the cost of use for users.

In-House Environmental 240TPH Asphalt Mixing Plant Feature and Application

240TPH In-House Environmental Asphalt Mixing Plant, the capacity is same as traditional AMP3000 model plant. It’s the real factory of asphalt mixture. It’s the best choice for the industry zone and city, where has very strict environmental protection regulation or has the limitation for the height of buildings. It can meet you different requirements. It has stable performance. It’s getting warm reception in China now. We believe that in the near future, In-House Environmental Asphalt Mixing Plant will completely replace traditional asphalt mixing plants and promote them globally due to its special characteristics.